PVC additives play a pivotal role in enhancing the properties of polyvinyl chloride. They improve durability, resistance to UV rays, and flexibility, ensuring PVC products' longevity and performance across various applications.

PVC stabilizers play a crucial role in PVC pipe production. They enhance the pipe's resistance to heat, UV rays, and chemical corrosion, ensuring its durability and safety in various applications.

In PVC foam board production, foaming agents create the desired porosity, while defoaming agents eliminate unwanted bubbles. These additives work together to ensure a uniform, high-quality foam structure, enhancing the board's performance and aesthetics.

PVC stabilizers are essential in PVC profile production, enhancing the material's stability and durability. They protect against degradation from heat, UV light, and chemical exposure, ensuring consistent performance and longevity in diverse applications.

PVC stabilizers are vital in PVC WPC production, bolstering the composite's resistance to weathering and degradation. They ensure consistent performance, durability, and aesthetics, making PVC WPC a reliable choice for various applications.

PVC stabilizers play a crucial role in PVC sheet production, enhancing its resistance to heat, UV radiation, and chemical attack. These additives ensure the sheet's durability, clarity, and stability, making it suitable for a wide range of applications.

PVC additives play a pivotal role in PVC pipe fitting production. These additives enhance the pipe fitting's durability, performance, and aesthetics, ensuring its reliability in various applications.

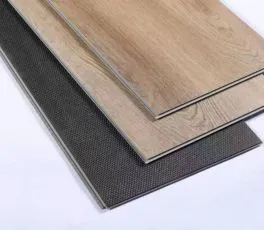

PVC additives, including stabilizers, foaming agents, foam regulators, impact modifiers, lubricants, processing aids, and anti-shrinkage strength agents, are crucial in SPC production. They ensure the material's durability, performance, and stability, making SPC a reliable choice for various applications.

Foaming agents play a vital role in PE mats production, introducing air bubbles to create a lightweight yet durable material. They enhance insulation properties and reduce costs, making PE mats an ideal choice for various applications.

In PVC mats production, foaming and blowing agents create a lightweight, porous structure, while PVC stabilizers ensure durability and resistance to degradation. Together, these additives optimize PVC mats performance and aesthetics.

Foaming and blowing agents are essential in PVC shoe production, lightweighting the material and enhancing comfort. They create a soft, flexible texture, perfect for casual and sports footwear.

PVC stabilizers play a crucial role in PE shoe production, improving the material's durability and resistance to wear and tear. They ensure the shoes maintain their shape and performance, even under heavy use.